A basketball jersey may appear simple at first glance, but behind its clean lines and bold colors lies a carefully made product shaped by culture, technology, and evolving player demands. From professional leagues to grassroots academies, jerseys must deliver comfort, durability, and visual impact simultaneously. Understanding how these garments by makers such as Custom Basketball Jersey Manufacturers in Brazil are made offers valuable insight for teams and brands looking for quality and consistency. This blog explores lesser-known realities that impact how basketball jerseys are produced, reveals the insider facts that show the depth of expertise that is involved in modern manufacturing.

1. Cultural Influence Quietly Drives Visual Identity

Probably the least considered factor of making a jersey is the impact of the culture around on the choices of the design that the local design teams usually get their ideas from the rhythm, movement, and typical sports traditions which are then reflected in the seamless patterns, lively typography, and vibrant color distribution. Rather than relying on rigid or boxy aesthetics, manufacturers emphasize motion-friendly visuals that look alive during play. This design mindset results in jerseys that feel distinctive without being overly complex, enabling teams to stand out while maintaining a professional appearance on the court.

2. Fabric Innovation Is Treated as a Performance Science

Modern jersey manufacturing is grounded in textile engineering rather than basic material selection. Breathability is only the starting point, fabrics are tested for moisture dispersion speed, stretch recovery, and resistance to friction during contact-heavy gameplay. Many production facilities invest heavily in fabric trials to ensure jerseys perform consistently across long seasons. In fact, benchmarking against international innovators such as DRH Sports, similar to Custom Basketball Jersey Manufacturers in Japan, has resulted in the advancement of manufacturers in terms of adopting precision-knit structures and multi-layer fabric compositions that not only provide ventilation but also ensure the fabric's structural integrity.

Fabric Development:

- Thermal Regulation Focus: Specialized weaves help regulate body temperature during extended play.

- Stretch Recovery Control: Fibers are engineered to snap back without sagging or warping.

- Contact-Ready Surfaces: Smooth textures reduce irritation during high-contact situations.

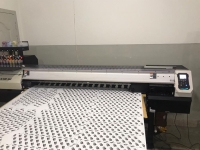

3. Customization Systems Prioritize Flexibility Over Volume

A common misconception is that large-scale production automatically guarantees efficiency, but jersey customization thrives on adaptability. Many manufacturers structure their workflows around modular systems that allow quick transitions between different team requirements. This method makes it easier to accommodate unique fonts, layered logos, sponsor placements, and last-minute roster updates without delaying delivery schedules. The emphasis is not just on producing more jerseys, but on the right jerseys with accuracy and speed, which is increasingly vital in competitive sports environments.

4. Quality Control Is Shaped by International Standards

Quality assurance processes are far more rigorous than simple visual inspections. Each jersey undergoes multiple checkpoints, including seam stress testing, print adhesion analysis, and size consistency verification. These standards are aligned with global expectations, taking cues from regions known for meticulous craftsmanship. For instance, lessons drawn from Custom Basketball Jersey Manufacturers in Spain have influenced stricter stitching tolerances and cleaner finishing methods, assuring that jerseys hold up under repeated washing and intense match conditions.

Quality Assurance:

- Seam Reinforcement Testing: High-stress areas are checked for long-term durability.

- Print Longevity Checks: Graphics are tested to prevent cracking or peeling.

- Consistent Fit Audits: Size grading is verified across all production runs.

5. Sustainability Is Evolving Into a Strategic Advantage

Environmental responsibility is no longer treated as an optional add-on; it is becoming a core manufacturing value. Many facilities are transitioning to recycled polyester yarns, low-water dyeing techniques, and eco-conscious inks to lessen their environmental footprint. Beyond compliance, sustainability now plays a role in brand perception and long-term partnerships. Manufacturers increasingly study practices followed by Custom Basketball Jersey Manufacturers in France, where eco-friendly production aligns closely with premium positioning, impacting sourcing strategies and process upgrades.

Final Thoughts: Understanding the Depth Behind Every Jersey

Basketball jerseys represent far more than team colours and player numbers; they embody design intelligence, material science, and operational precision. From culturally influenced aesthetics and advanced fabric engineering to flexible customization models, globally benchmarked quality control, and sustainability-driven innovation, every stage of production reflects deliberate choices. Recognizing these insider facts allows teams, academies, and brands to make informed decisions when sourcing jerseys that not only look impressive but also perform reliably and endure the demands of the game.