Across corporate, hospitality, education and retail sectors, approved brands are fundamentally rethinking how apparel contributes to brand strength. Branded polo shirts, which used to be only a basic part of the uniform, have turned into the most tangible and communicative elements of the brand of the staff showing it as professional, trustworthy and value-driven. As competition intensifies and customer perception becomes more nuanced, brands are moving away from mass-produced options toward Custom Polo Shirts Manufacturers in USA, like DRH Sports, that provide them with control, consistency and trustworthiness.

1. Brand Consistency Has Become Non-Negotiable

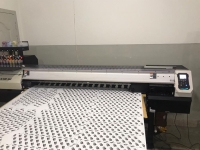

Approved brands operate under strict visual and operational guidelines, and apparel inconsistency can dilute brand authority faster than almost any other element. Custom polo shirt manufacturers allow brands to standardise exact color palettes, fabric finishes, logo dimensions, and fit profiles across repeated orders. This level of control ensures that staff uniforms look identical across departments, locations, and timelines, reinforcing trust and recognition. Unlike generic suppliers that rely on seasonal fabric changes, custom partners preserve specifications over long periods, allowing brands to maintain a unified appearance as they grow.

2. Fabric Quality Is Now a Competitive Differentiator

Fabric attributes have become one of the major factors brand representatives consider when approving a brand for which they expect the apparel to be used daily and still keep a neat look. Custom manufacturers invest heavily in sourcing and testing premium blends that offer breathability, softness, and resilience without compromising structure. Many brands evaluate these materials against international benchmarks, including practices followed by Custom Polo Shirts Manufacturers in Australia, where climate-driven fabric innovation has set high standards for durability and comfort. The result is polos that feel refined on day one and they can still be worn for several months being able to retain their neatness.

Fabric Advantage:

- Enhanced Color Retention: Advanced dyeing techniques prevent fading even with frequent washing.

- Comfort-Driven Weaves: Breathable structures lower heat buildup during long wear.

- Reduced Wear Deformation: Fabrics resist stretching, pilling, and collar collapse over time.

3. Customization Enables Subtle Yet Powerful Brand Storytelling

Today’s strongest brands communicate through details, not excess. Custom polo shirt manufacturing enables exact customization that supports brand storytelling without appearing loud or promotional. From refined collar constructions and tonal embroidery to carefully positioned logos and signature stitching, these small elements create a cohesive visual language. Approved brands value this subtlety because it allows uniforms to align with broader brand aesthetics rather than looking like promotional merchandise. Customization, when done thoughtfully, transforms a polo shirt into a wearable extension of brand philosophy.

4. Production Flexibility Supports Scaling Without Compromise

As approved brands expand their workforce, enter new markets, or onboard seasonal teams, flexibility in production becomes essential. Custom manufacturers are structured to handle fluctuating order volumes while maintaining identical specifications. This adaptability reduces overstock, minimises waste, and allows brands to place repeat orders with confidence. Manufacturing models inspired by Custom Polo Shirts Manufacturers in UK emphasize scalable workflows that balance efficiency with meticulous quality checks, ensuring growth does not come at the cost of consistency or reliability.

Operational Efficiency:

- Scalable Order Management: Manufacturers support both pilot runs and nationwide rollouts.

- Predictable Lead Times: Streamlined processes lessen delivery uncertainty.

- Design Continuity: Approved styles can be reproduced accurately across multiple seasons.

5. Ethical Manufacturing and Sustainability Are Now Approval Essentials

Environmental and ethical aspects are increasingly being taken into account by buyers when deciding on suppliers. Custom manufacturers are better positioned to meet these expectations by providing transparency in sourcing, labor practices and production methods. Sustainable initiatives such as recycled fibers, low-impact dyes and responsible waste management are becoming standard needs rather than optional features. This mirrors practices seen among Custom Polo Shirts Manufacturers in Canada, where sustainability is seen as a prerequisite for brand trust and meeting regulatory requirements in the long run.

Final Thoughts: Custom Manufacturing as a Long-Term Brand Investment

The growing shift toward custom polo shirt manufacturers reflects a deeper understanding of apparel’s role in brand performance. Uniforms have ceased to be mere operational by-products of approved brands; they have become strategic assets that have an impact on the perception, employee morale, and customer loyalty. Through consistent branding, superior fabrics, thoughtful customisation, scalable production and ethical alignment, custom manufacturing delivers measurable long-term value. As brand standards continue to rise, switching to custom partners is not merely a trend; it is a strategic investment in credibility, control, and sustainable growth.